Digital Air Jet sieve shaker

03/07/2017

Water baths

04/07/2017Universal Testing Machine – Automatic computerized system

Mesin uji tarik baja dan tekan beton, dengan kapasitas 1000kN(tarik) dan 2000kN(tekan)

Brand : Controls – Italia

Standard : EN 15630-1; EN 15630-3; EN 10080; UNI EN ISO 6892-1

Model : 70-C0820/C

Deskripsi Umum:

Mesin ini dibuat khusus untuk memenuhi kebutuhan pengujian untuk di pusat laboratorium maupun laboratorium komersil untuk industri ataupun dunia teknik sipil pada umumnya. mesin universal ini dapat digunakan untuk uji tarik baja sampai pada diameter 40mm atau pipih sampai 35x75mm, dan baik juga untuk digunakan pada uji tekan beton. dengan menggunakan aksesoris tambahan mesin ini dapat melakukan uji “transverse and bending” pada baja atau uji lentur pada balok beton.

Semua kendali dilakukan melalui PC yang sudah disupplai pada waktu pembelian. software pun sudah termasuk didalamnya yang dapat digunakan untuk uji tarik, tekan, bending, dan flexure.

Fitur Utama :

- 1000 kN Kapasitas tarik dan 2000 kN kapasitas tekan

- Sepenuhnya dapat mengendalikan jalannya percobaan secara otomatis sampai pada hasil pengujian yang berupa sertifikat dengan dengan tombol sederhana.

- Strain gauge load cell terintegrasi pada Piston, menampilkan pengukuran beban yang sangat akurat.

- Rapid vertical displacement of mobile frame by remote control

- Hydraulic gripping system controlled by remote control

- Termasuk 3 set grip untuk baja dengan penampang lingkaran sampai diameter 40 mm. dan profil pipih sampai 70×35 mm

- Pemasangan spesimen dari sisi depan untuk kemudahan dan kecepatan pada jalannya pengujian

- Menampilkan diagram Stress/strain selama pengujian

- Pencetakan diagram hasil pengujian untuk stress/strain dan hasil pengujiannya.

Frame Mesin, Kesatuan silinder dengan load cell

- Frame/rangka yang kaku dengan berbahan dasar baja solid namun rendah(untuk kemudahan) untuk penempatan grip.

- Piston/kesatuan silinder terpasang pada bagian atas rangka kaku, load cell sudah menjadi kesatuan dengan piston.

- Mobile frame consisting of four high tensile strength columns, upper crosshead directly connected to the piston, intermediate crosshead with compression platen and lower crosshead housing the upper grippers.

- Hydraulically operated gripping system and vertical adjustment by two independent auxiliary cylinders controlled by the push button panel. This unique feature make the machine extremely easy to operate enabling one man to perform the test in a very short time.

- Crosshead displacement controlled by the use of a bi-directional encoder.

Control console

- The lower section houses the hydraulic assembly which include: Hydraulic pump, Proportional valve, Hydraulic valves, Heat exchanger to control the oil temperature and the Oil tank.

Grippers

- Three sets of standard grippers supplied with the machine, for rounds and flats, plus two sets of grip liners to provide maximum bearing and holding surface for specimens of all sizes.

Safety features

- Pressure switch, which automatically stops the machine when the oil pressure goes over the maximum permitted level.

- Max travel limit switch to stop the mobile frame at its upper position.

- Software feature which stops the machine when the maximum load is reached.

Hardware

The upper section of the control console houses the electronic card for the control of all functions, having the following specifications:

- A/D converter resolution 1/20000

- No. 4 outputs for electrovalves

- Analogical output for load and strain control:12 bit

- Load cell input

Software

The machine can be used either in the manual or in the automatic mode to perform:

- Tensile test on steel reinforcing bars conforming to EN 10002 and ASTM A370

- Tensile tests in general, flexural (transverse) and bending test on steel conforming to ASTM E290, UNI 564.

- Flexural tests on concrete beams conforming to EN 12390-5

- Compression tests on concrete specimens conforming to EN 12390-3

Aksesoris standar bawaan

Mesin ini sudah dilengkapi dengan aksesoris:

- No. 3 sets of grips for round specimens up to 40 mm dia. and flat specimens up to 70 mm wide and 35 mm thick and two sets of grip liners.

- No. 1 set of foundation bolts, 1 service spanner, instruction manual, PC and colour graphic printer

Spesifikasi teknis :

– Kemampuan Maximum pada uji tarik: 1000 kN (100Ton)

– Kemampuan Maximum pada uji tekan: 2000 kN (200Ton)

– Kecepatan Maximum piston : 83 mm/min

– Kecepatan penyesuaian balok/batang utama/Crosshead: 500 mm/min

– Perpanjangan Maximum piston: 610 mm

– Jarak antar kolom: 330 mm

Dimensis:

– Frame Penguji (piston fully out): 955 x 635 x 3960 mm

– Konsol pengendali : 565 x 540 x 1350 mm

Berat dan kubikasi pengiriman (mendekati.):

– Rangka Uji: 2900 kg

– Konsol kendali: 200 kg

– Total Berat kotor: 4000 kg

– Dimensi kubikasi: 7 m3

Ordering Info :

70-C0821

Computer controlled Universal Testing Machine, for tension tests up to 1000 kN and compression tests up to 2000 kN, complete with three set of standard grips, PC, printer and software. 380 V, 50 Hz, 3 ph.

Aksesoris : hanya dipilih yang sesuai dengan kebutuhan

ELECTRONIC COAXIAL EXTENSOMETERS

These extensometers are basically made from three separate aluminium tubular sections, joined telescopically to one another. The middle section, delimited by the larger diameter, determines the measuring base, which is 5 times the diameter of the specimen. The two end sections consist of two mechanisms for gripping the specimen. One carries the electrical extensometer, the other an anvil.

70-C0961/A2

Coaxial electronic extensometer for round specimens from 5 to 11,5 mm dia.

70-C0961/B2

Coaxial electronic extensometer for round specimens from 11 to 18 mm dia.

70-C0961/C2

Coaxial electronic extensometer for round specimens from 17,5 to 26 mm dia.

70-C0961/D1

Coaxial electronic extensometer for round specimens from 26 to 36 mm dia.

70 C0961/E

Coaxial electronic extensometer to measure the elongation of strands from 9 to 15,2mm dia. up to failure. Gauge length: 600 mm; Max travel: 50 mm.

NOTE: Requires frame upgrade code C0820/UP

UNIVERSAL EXTENSOMETERS

70-C0954/C1

Standard electronic extensometer.

Fitted with high precision electronic linear transducer. Maximum travel 10 mm, measuring base 200 mm. It has to be removed before sample failure.

70-C0953/C

Mechanical extensometer. Suitable flat samples up to 40 x 40 mm, rounds from 0.4 mm to 40 mm diameter. Base length: 50, 100 and 200 mm. Dial gauge 10 x 0.01mm.

ACCESSORY FOR ELECTROWELDED SCREEN

70-C0901/20

Test accessory for electrowelded steel screen. Used with the standard grips for flat specimens.

GRIPS FOR STRAND WIRES

70-C0901/31

Grip for seven cord strands 9.3 to 15.2 mm dia. Four pieces required.

Weight approx.: 5 kg.

COMPRESSION TESTS ON CONCRETE SPECIMENS

70-C0820/5

Compressione device for 70-C0820/C. Includes: upper and lower platens dia. 216x50mm, spherical seat, distance pieces dia. 200x100mm and dia. 200x50mm. Resulting vertical daylight approx. 310mm.

70-C0901/5

Set of compression platens for concrete specimens. Upper platen fit with spherical seat.

Platen dimensions: 310x435x50 mm.

FLEXURAL TESTS ON CONCRETE SPECIMENS

Standards: ASTM C78, AASHTO T97, EN 12390-5

50-C9010/B

Flexural device for concrete beams 100x100x400/500 mm and 150x150x600/700 mm.

SPLITTING TEST (INDIRECT TENSILE) ON CONCRETE SPECIMENS

Standards: ASTM C496, EN 1338, EN 12390-6

50-C9000/B

Splitting tensile test device for cylinders up to dia. 160×320 mm, conforming to ASTM C496 and EN 12390-6.

Weight approx..: 28 kg

50-C9000/A

Splitting tensile test device for cylinders dia. 250×500 mm, conforming to EN 12390-6.

Weight approx..: 50 kg

50-C9070/B

Splitting tensile test device for cubes up to 150 and

block pavers conforming to EN 1338 and EN 12390-6.

Weight approx..: 28 kg

50-C9002

Hardboard packing strips 4x15x345 mm to EN1338 and EN 12390-6. Pack of 50.

50-C9002/A

Plywood packing strips 3x25x345 mm to ASTM C496. Pack of 50.

50-C9001/A

Hardboard packing strips 4x15x550 mm for 50-C9000/A. Pack of 50.

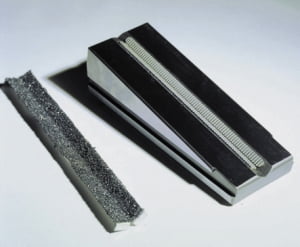

TRANSVERSE TEST ATTACHMENT

70-C0820/2

Transverse test attachment. See picture No. For use with 70-C0820/C tester to perform the transverse test on steel specimens conforming to UNI 559 Standards.

- Max. load 200 kN

- Max distance between bearers 800 mm

- Bearers: length 120 mm x 50 mm dia.

- Weight approx.: 100 kg

BENDING TEST ATTACHMENT

70-C0820/31

Bending test attachment. See picture No. For use with 70-C0820/C tester to perform the bending test on steel specimens conforming to ASTM E290 and UNI 564.

- Max. load 200 kN

- Max distance between bearers 800 mm

- Bearers: length 120 mm x 50 mm dia.

- Weight approx.: 150 kg

ELASTIC MODULUS DETERMINATION ON CONCRETE

(Possible to be performed only by connecting a second compression frame, see code 70-T10/2F in the Upgrading Options)

55-C0222/G

Electronic universal compressometer-extensometer for cylinders and prisms. Supplied with adapter for small specimens, template for correct mounting and elastic bands holding the devices onto the specimen.

NOTE: Other sensor types (such as strain gauges) are available on request. Ask our technical department.

82-SW/EM

E-MODULE Software for Poisson ratio and Elastic Modulus determination.

SPARE PARTS

70-C0807/10

Gripper for flat specimens up to 70×35 mm and round specimens from 5 to 9 mm dia. Four pieces are required per set.

70-C0807/12

Vee gripper for round specimens from 9 to 19 mm dia. Four pieces are required per set.

70-C0807/14

Vee gripper for round specimens from1 9 to 40 mm dia. Four pieces are required per set.

70-C0807/16

Grip liner 9 mm thick. Four pieces are required per set.

70-C0807/18

Grip liner 14 mm thick. Four pieces are required per set.

70-C0901/21

Graphite grease for grips. 1 kg can.

Kategori : baja

Price/konsultasi kebutuhan mesin : Call For Info

Yudhistira

Hp. 0811 188 6845;

– 0818 0816 0634(WA)

Email : naysite2@gmail.com;

Reviews

There are no reviews yet.