Emulsified asphalt distillation apparatus 81-B0153

09/09/2020

Oxigen permeameter. Cembureau method

16/02/2021Uji Kuat Tarik Baja Beton dengan Universal Testing Machine – HPT Series

Mesin Uji Tarik Baja dan Tekan Beton dengan kapasitas 1000, 1200, 1500, 2000 kN

Brand/Supplied From : Controls – Italia

Standard : EN ISO 6892, EN ISO 7500-1, ASTM A370, EN ISO 15630-1

Kode Barang : 70 – T10H02

Fitur Utama :

- Ideal pada dunia Industri Konstruksi

Meski angat cocok pada dunia konstruksi namun penggunaannya bisa digunakan pada uji tarik/tegang pada baja melingkar maupun baja datar dan uji tekan maupun uji belah pada beton. - Kapasitas yang Cukup

Dari 1000kN sampai kapasitas 2000kN - Menggunakan Rangka 4 Kolom kokoh

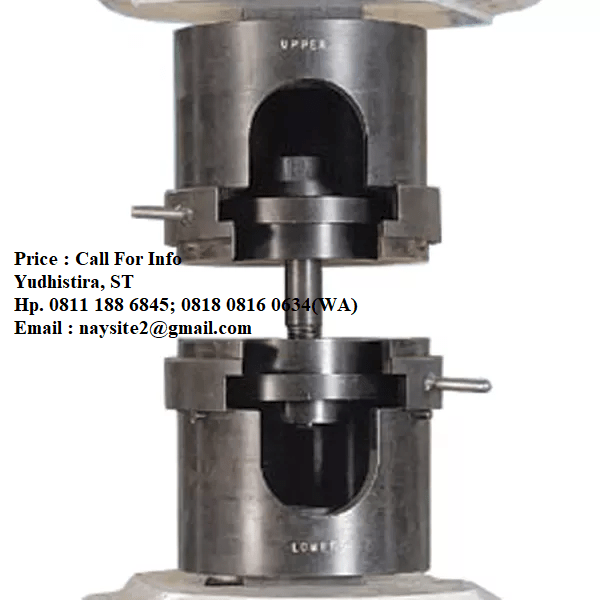

Rangka empat kolom yang sangat kaku dan kokoh dengan jarak bebas vertikal besar yang sesuai untuk uji tarik dan tekan - Bukaan yang sejajar

Untuk memudahkan memasukan sampel uji tarik. Pengait dan gagang dapat dilepas dengan mudah hanya dengan menariknya dari depan. Sistem pegangan hidrolik dioperasikan oleh panel tombol tekan - Menggunakan Load Cell dengan akurasi Tinggi

Pengukuran bebean menggunakan Load Cell dengan ketelitian tinggi yang memberikan bacaan akurat dari awal pembebanan sudah terbaca. - Memungkinkan untuk penggunaan Aksesoris tambahan yang luas

UTM ini dapat menjalankan banyak variasi pengujian, termasuk Etensometers, Transverse and Bending test apparatus for steel, Compression-Flexural and Indirect tensile test on concrete, etc. - Kendali dengan PC

Pengujian dilakukan secara otomatis melalui PC dan software - Software pendukung sudah termasuk

Disuplai bersama dengan software pengatur yang mempunyai jangkauan yang luas untuk kebutuhan pengujian pada baja, beton, dan material konstruksi lainnya. - Terdapat slot untuk kendali frame tambahan

Memungkinkan untuk menghubungkan frame kompresi beton hingga kapasitas 5000kN atau frame uji Lentur.

General Descriptions :

Powerful hydraulic system which offers high test throughput improving efficiency of the laboratory.

High flexibility covering the following applications:

- Steel

- Tensile tests on steel rebars and rounds up to 78 mm dia.

- Tensile test on steel flats up to 72 x 100 mm

- Tensile tests on wire strands and electro-welded steel screen

- Transverse tests on steel specimens

- Bend and re-bend tests on steel specimens

- Brinell with 10mm ball

- Shear tests on rounds

- Concrete

- Compression tests on cubes and cylinders

- Flexural tests on concrete beams

- Indirect tensile on cylinders, cubes and paving blocks

- Determination of the Modulus of elasticity (in a second dedicated frame)

- Pull out test

- Various

- Compression tests on rock, masonry units, refractories etc.

- Wire rope tensile tests

- Nut and bolt testing

- Tensile test on headed and shouldered specimens

The range includes four models of 1000 kN, 1200 kN, 1500 kN and 2000 kN cap. All models are controlled by the new and sophisticated HPU 200 control unit and are complete with PC, upper and lower hydraulically operated jaws, complete set of grips for rounds and flats, transverse test attachment and high precision load cell providing high accuracy from the very beginning of the load scale.

Loading frame

The frame consists essentially of a robust four columns frame with three sturdy crossheads: upper is directly connected to the lower one by two main columns; the middle one, moving on two screw columns, can be adjusted through an electric motor by using the dedicated push button panel, in order to set the required vertical daylight both for compression and tensile tests; the lower is controlled by a simple effect piston centrally positioned. Jaws and wedge grips are included . The tensile jaws are directly operated by the Power control console with a push-button panel. The compression tests are performed between the lower and the mobile middle crossheads, using the suitable accessories.

Power and control console – HPU 200

Control console HPU 200 features space-saving ergonomic design with small footprint and houses the hydraulic power unit, the electronic system and the PC to manage all the control functions.

Automatically performs steel tensile testing, compression, splitting tests, Elastic Modulus and Poisson’s ratio determination on concrete specimens. See Accessories.

PC and software enable remote control of the complete system.

The system can be upgraded for a second frame connection and control by a special hydraulic valve system (70-T10/2F). Normally adopted to connect a concrete compression frame up to 5000 kN capacity, to perform not only compression, but other important tests as for example the Modulus of Elasticity, with the related software (model 82-SW/EM). Selection of the test frame via software.

For more info see Technical Specifications.

Safety features

- Pressure valve that automatically stops the machine when the oil pressure approaches the limit

- Maximum travel limit switches to control the position of the mobile crosshead

- Software stops the machine when the maximum load is reached

- Emergency stop button

TECHNICAL SPECIFICATIONS TABLE

| Model | HTP-1000 | HTP-1200 | HTP-1500 | HTP-2000 |

| Code | 70-T10H02 | 70-T12H02 | 70-T15H02 | 70-T20H02 |

| Cap. | 1000 kN | 1200 kN | 1500 kN | 2000 kN |

| Load sensor | High accuracy load cell | High accuracy load cell | High accuracy load cell | High accuracy load cell |

| For rounds up to mm dia. | 60 | 60 | 60 | 78 |

| Set of grips for rounds mm dia. | 8 to 18 12 to 30 25 to 38 38 to 50 |

8 to 18 12 to 30 28 to 40 38 to 50 |

8 to 18 12 to 30 28 to 40 38 to 50 |

8 to 18 12 to 30 30 to 42 42 to 54 54 to 66 |

| For flats mm | 0 to 20 x 90 20 to 40 x 90 40 to 60 x 90 |

0 to 15 x 100 15 to 30 x 100 30 to 45 x 100 45 to 60 x 100 |

0 to 15 x 100 15 to 30 x 100 30 to 45 x 100 45 to 60 x 100 |

0 to 18 x 100 18 to 36 x 100 36 to 54 x 100 54 to 72 x 100 |

| Piston travel mm | 250 | 250 | 250 | 300 |

| Max adjustable tensile daylight mm | 50-850 | 50-850 | 50-850 | 50-850 |

| Max daylight between grippers mm* | 600 | 600 | 600 | 550 |

| Max compression daylight (without accessories) mm | 0-850 | 0-850 | 0-850 | 0-850 |

| Horizontal daylight mm | 750 | 750 | 750 | 850 |

| Maximum piston speed (no load condition) mm/min | 190 | 100 | 100 | 100 |

| Crosshead adjustable speed mm/min | 360 @ 50 Hz 430 @ 60 Hz |

275 @ 50 Hz 330 @ 60 Hz |

275 @ 50 Hz 330 @ 60 Hz |

225 @ 50 Hz 275 @ 60 Hz |

| Load resolution kN | 0,01 | 0,02 | 0,02 | 0,02 |

| Crosshead displacement resolution mm | 0,01 | 0,01 | 0,01 | 0,01 |

| Machine class 1 range (EN ISO 7500-1) |

10-1000 kN | 12-1200 kN | 15-1500 kN | 20-2000 kN |

| Overall dimensions: Frame, l x d x hConsole, l x d x h |

1,1 x 0,66 x 3,0/3,25 0,8 x 0,9 x 1,55 |

1,2 x 0,9 x 3,25/3,5 0,8 x 0,9 x 1,55 |

1,2 x 0,9 x 3,25/3,5 0,8 x 0,9 x 1,55 |

1,5 x 1,0 x 3,7/4,0 0,8 x 0,9 x 1,55 |

| Weight approx.: Frame kg Console kg |

3700 kg 180 kg |

6000 kg 180 kg |

6000 kg 180 kg |

8000 kg 180 kg |

*Max distance between grips to exploit the full pisotn travel

HPU POWER AND CONTROL CONSOLE

Hardware

- 131.000 points effective resolution

- Control frequency 250 Hz

- Sampling rate 500 Hz

- Closed-loop P.I.D.control

- 6 channels (one dedicated to crosshead displacement) to measure elongation/displacement/strain with potentiometric, conditioned LVDT and magnetostrictive transducers

- 4 channels for strain measurements with strain gauges

- 2 channels for load sensors: load cell and load cell/pressure transducer of possible second frame

- simple multi-sensors connection and calibration file selection

- digital linearization of the calibration curve. (multi-coefficient)

Hydraulics

- Dual stage pump: centrifugal low pressure for fast approach (max. flow rate 9 l/min ) automatically switching to radial multi- piston high pressure (max. flow rate 3.2 l/min) for loading

- Oil flow control by servo-controlled proportional valve

- AC motor 3000 W

- Maximum working pressure 700 bar

- Oil temperature controlled by air cooling system

- Console cabinet lined with soundproofing material for operator’s comfort.

- Tank capacity: 30 liters

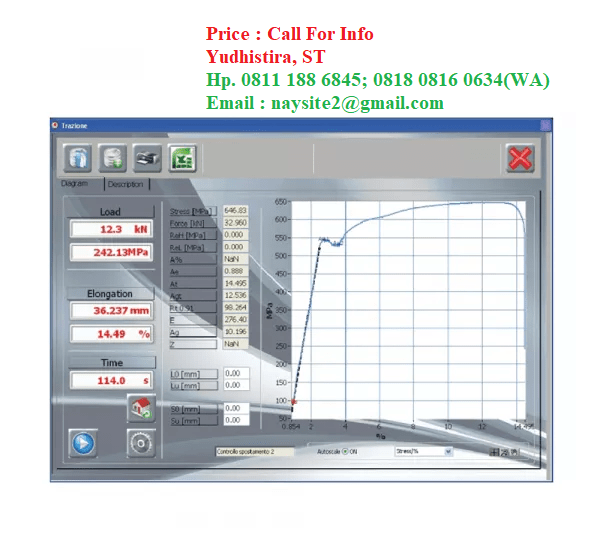

MANAGEMENT SOFTWARE AND SOFTWARE PACKAGES

HPT Universal testers are supplied complete with RTM (Real Time Management) user interface environment allowing:

- Remote control of the complete system for automatic test execution: quick platen approach, zeroing, test execution according to the selected test type, calculation of results, graphical and numerical management of results

- Storage of single and multiple tests

- Printing of customized test reports for both single and multiple tests

- Real time and deferred management of tests data and results, either in numeric or in graphic format

- Language selection (Latin characters only)

- Units selection

- Remote technical assistance/diagnostic via internet

The following Software packages are also included in the system:

- UTS Software Specifically designed for tensile testing under load/stress control and crosshead separation control (by using the displacement transducer supplied with the machine), allowing:

- Simultaneous display of stress/time, stress/elongation %, elongation/time and stress/elongation;

- Possibility to overlap two elongation/stress graphs: one obtained with the included displacement transducer measuring crosshead separation travel and the other obtained w ith an optional extensometer (coaxial or universal);

- Elaboration of tension test results: ReH, ReL or Rp (calculated at three different elongation percentages selectable by the user), A, Ag, At, Agt, Ae, Rt, Z, elastic modulus E, etc, conforming to EN ISO 6892-1 and EN 15630-1 for steel rebars.

- DATAMANAGER Software For compression, flexure and indirect tensile test on concrete, cement specimens and other construction materials allowing:

- Real time monitoring of test data and stress/time graph

- Automatic load detection failure and storage

- Cement testing to EN 196-1 guided test procedure

- Saving of batch file with automatic calculation of average and standard deviation

The following software package is available as option when upgrading the machine with the hydraulic system for a second frame connection (see 70-T10/2F).

- E-MODULE software For Poisson ratio and Elastic Modulus determination on concrete specimens allowing:

- Free unlimited programmable load/stress cycles to fulfill any kind of test procedure

- Real time monitoring of test data, stress/time, stress/axial strain, stress/lateral strain graphs

- Automatic verification of sample centering and sensors functionality, as per Standard requirements

- Automatic calculation of Initial and Final secant Elastic Modulus values

Ordering Info :

1000kN CAPACITY

70- T10H02

HPT-1000, Automatic Computerized Universal Testing Machine, 1000 kN cap. HPU 200 control console. Load measurement by high precision load cell. Supplied complete with PC, upper and lower hydraulically operated jaws, four set of grippers for rounds from 8 to 50 mm dia., three set of grippers for flats from 20 x 90 to 60 x 90 mm and transverse test attachment. Including also Management software and Software packages for tensile steel testing, compression flexural and indirect tensile testing on concrete and other similar materials. 380 V, 50 Hz, 3 ph.

1200kN CAPACITY

70- T12H02

HPT 1200, Automatic Computerized Universal Testing Machine, 1200 kN cap. HPU 200 control console. Load measurement by high precision load cell. Supplied complete with PC, upper and lower hydraulically operated jaws, three set of grippers for rounds from 8 to 50 mm dia., four set of grippers for flats from 15 x 100 to 60 x 100 mm and transverse test attachment. Including also Management software and Software packages for tensile steel testing, compression flexural and indirect tensile testing on concrete and other similar materials.

380 V, 50 Hz, 3 ph.

1500kN CAPACITY

70- T15H02

HPT 1500, Automatic Computerized Universal Testing Machine, 1500 kN cap. HPU 200 control console. Load measurement by high precision load cell. Supplied complete with PC, upper and lower hydraulically operated jaws, three set of grippers for rounds from 8 to 50 mm dia., four set of grippers for flats from 15 x 100 to 60 x 100 mm and transverse test attachment. Including also Management software and Software packages for tensile steel testing, compression flexural and indirect tensile testing on concrete and other similar materials.

380 V, 50 Hz, 3 ph.

2000kN CAPACITY

70- T20H02

HPT 2000, Automatic Computerized Universal Testing Machine, 2000 kN cap. HPU 200 control console. Load measurement by high precision load cell. Supplied complete with PC, upper and lower hydraulically operated jaws, three set of grippers for rounds from 8 to 66 mm dia., four set of grippers for flats from 18 x 100 to 72 x 100 mm and transverse test attachment. Including also Management software and Software packages for tensile steel testing, compression flexural and indirect tensile testing on concrete and other similar materials.

380 V, 50 Hz, 3 ph.

Price : Call For Info

Yudhistira, ST

Hp. 0811 188 6845; 0818 0816 0634(WA)

Email : naysite2@gmail.com

Reviews

There are no reviews yet.